Changing the management system is pretty simple. But it does require a new wiring harness. Last I heard - which was a year or so ago - they were using the BigStuff3 system as standard. So Tim's system was probably one of the last ones sold.

www.bigstuff3.com But he also has a distributer, so it must be set up as fuel only.

BigStuff is still probably the hot ticket in aftermarket EFI. It has two really big advantages over the Haltech system. First, the Haltech is batch fired. That means all the injectors fire at once. It doesn't sound like it would work, but it does. BS3 is a sequential system, that fires each injector individually at the correct time. A much smoother and more efficient system - especially at low speeds. It also has a greater power potential.

Second (and this is the big one) it has dual wide band O2 sensors. It's a true closed loop system. It's also somewhat self adjusting for a great variety of situations - like altitude and weather. But, it still needs a solid baseline tune. You turn the O2 sensors off, tune the engine on a dyno, and then turn the sensors back on. After that, it will self adjust up to about 20% or so.

The BS3 system uses GM sensors. The first thing I would do is replace all of the sensors with real genuine GM parts. In my system, there's water temp, air intake temp, MAP, and TPS. That's only 4 sensors, not a lot of money. Lots of people have had trouble with the aftermarket brands, especially in performance applications.

The Momar system has a very unique problem with the TPS. Mine is on the rear of the right rear throttle body; Tim's is the same. Back in '04 we were trying to tune the system, and there was a bad throttle lag. Didn't run too well at all. Pull the sensor off, and take a look at it. Take a look at the stub of the throttle shaft that goes into the hole in the sensor. Mine had a huge mismatch. You'de step on the gas and the throttle blades would open. But the TPS didn't see small changes, so it didn't increase the fuel input. The engine bogged down and ran like crap.

I let the guys at S&S figure that one out. They found another sensor to use that didn't have that problem. Tim's should be OK, since it's a later system.

But it's easy to test for. Hook up the lap top and read the throttle position. Then open the throttle blades very slowly. The reading on the screen should match the blade opening. The throttle position on the screen should match the actual throttle position all the way from fully closed to fully open. If it doesn't, you can try adjusting it. If that doesn't work, you'll need to find a new sensor. You could also make it fit better with JB Weld Quick and seran wrap.

Next thing to do is check timing. My engine is real sensative to timing. At 34* it runs really well. Very smooth at all parameters. At 36* it starts to run bad - jerking and sputtering. At 38* it's almost undrivable. I use 10* intitial, 24* mechanical, and no vacuum advance.

Once you have those things set where they need to be, and everything is working as designed, you need to get to a dyno. EFI is very precise; much more so than a carb. The flip side of that is that it has to be set just right. Find a tuner that knows the BS3 system. Pay the money. It will be worth it.

My Haltech system is working really well. My engine runs like a dream, and makes a boatload of power. I'm going to make some mechanical changes and upgrades this winter. Maybe next winter I'll upgrade to the BS3 system.

This is my engine with the same air cleaners. I powder coated mine in translucent red.

Same engine with velocity stacks.

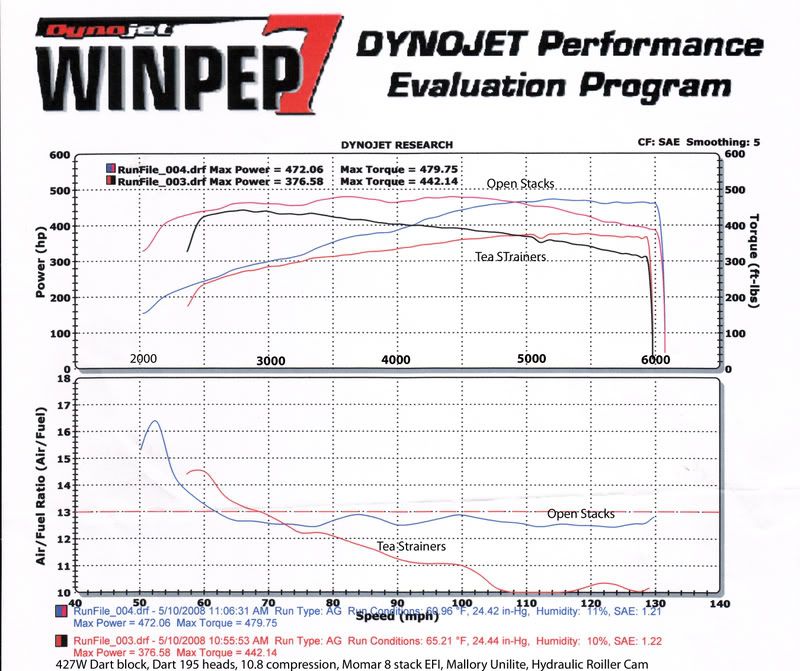

Here's a dyno sheet from earlier this year. Notice the two power curves. The two runs were done just a few minutes apart. The only differance is one is with open stacks, and the other is with the tea strainers installed. The tea strainers cost 100hp! I wouldn't have believed, if the proof wasn't right there. You can see how much the AFR drops, indicating a huge restriction.