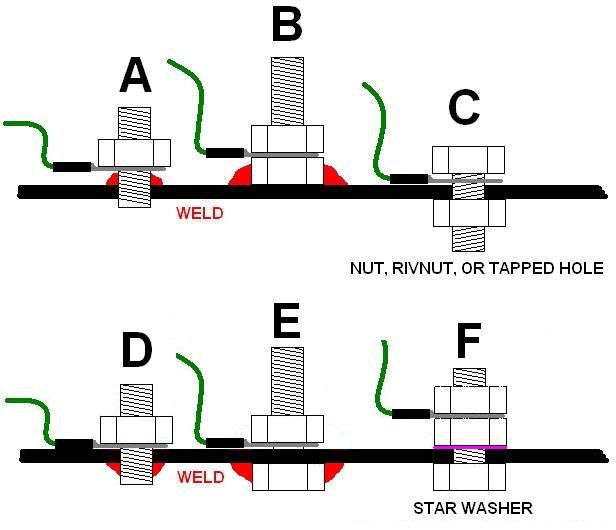

First off, I will be putting stainless bolts through frame elements, removing an area of powder coat on the front side, welding the bolt heads on the back side, and using star washers and copper washers under the conector on the front side. Kind of like "E" in this diagram from wildswing but with the additon of a star washer and a copper washer. If the weld is conductive, great, but I'm not relying on the weld conducting.

![Image]()

So with that our of the way, the question remains where and how large. I'm thinking a 3/8" for the main ground into one of the rear 2X3s under the upper trunk floor. One or two in the trunk for any electronics I may put there -- 5/16" or 1/4"? One in each corner in back for tail lights etc. in the rear 3/4" tube on either side of the quick jack mounts, one in each front corner (where? -- I'm not famiar with the nose aluminum yet). One big engine ground (3/8"?). Where else?

Mike

So with that our of the way, the question remains where and how large. I'm thinking a 3/8" for the main ground into one of the rear 2X3s under the upper trunk floor. One or two in the trunk for any electronics I may put there -- 5/16" or 1/4"? One in each corner in back for tail lights etc. in the rear 3/4" tube on either side of the quick jack mounts, one in each front corner (where? -- I'm not famiar with the nose aluminum yet). One big engine ground (3/8"?). Where else?

Mike